Idea Lounge

Business Cases of

projects delivered to our clients

Cost Take-Out

In the competitive chemicals industry, cost efficiency is paramount, especially for private equity-owned firms seeking to maximize returns. A leading chemicals company recently embarked on a Cost Take-Out strategic sourcing project targeting indirect procurement categories. By employing accelerated sourcing methods—including direct negotiations, ninja sourcing, demand management, strategic sourcing, and category re-scoping—the company achieved $5 million in EBITDA savings.

Procurement Transformation

State governments are under pressure to deliver more with fewer resources. This article highlights a procurement transformation project by a state government agency, yielding significant savings. The transformation focused on three key areas: redesigning the procurement department, streamlining operations through process mapping, and strategically sourcing IT hardware and software categories.

Distribution Lineman Optimization

A $9 billion electric utility addressed a shortage of qualified linemen for distribution line installations. The project aimed to meet local content requirements, ensure safety KPIs, and stay within a $1.6 billion budget over five years. Using advanced techniques, the company achieved $600 million in savings, increased local content from 12% to 23%, and reduced crew ramp-up times from 6-12 weeks to 1-3 weeks.

Supply Chain Systems Implementation

A Fortune 20 Supermajor oil and gas company wanted to deploy and implement their “backbone” supply chain systems across their global business units. The project deployed SAP, SAP Ariba, and Maximo as core systems, impacting over 2,000 staff. It included category management, staff training, capital project management, and process improvements, ensuring alignment with health, safety, and environmental regulations.

Bake Sheets Value Chain

A $7 billion prepared meals company sought to improve its bake sheet cleaning process to optimize its value chain. By evaluating labor, equipment, specifications, cycle times, and wastewater management, the company compared the current process with glazed bake sheets. The switch to glazed sheets led to projected savings of $12.3 million through reduced labor, faster cleaning cycles, lower overhead costs, and a 38% reduction in bake sheet damage.

Facilities Management Services Change Management

A Fortune 10 oil and gas supermajor was initiated to coral and bring under management the disparate materials and services. The company, overseeing 16 refineries and 510 suppliers, faced challenges in supplier management, invoice processing, and cost control. By consolidating services and awarding contracts to 85 FMS providers, the company realized $3.2 million in annual savings, reduced invoices by 60%, avoided late payment penalties, and enhanced service task visibility using project management software.

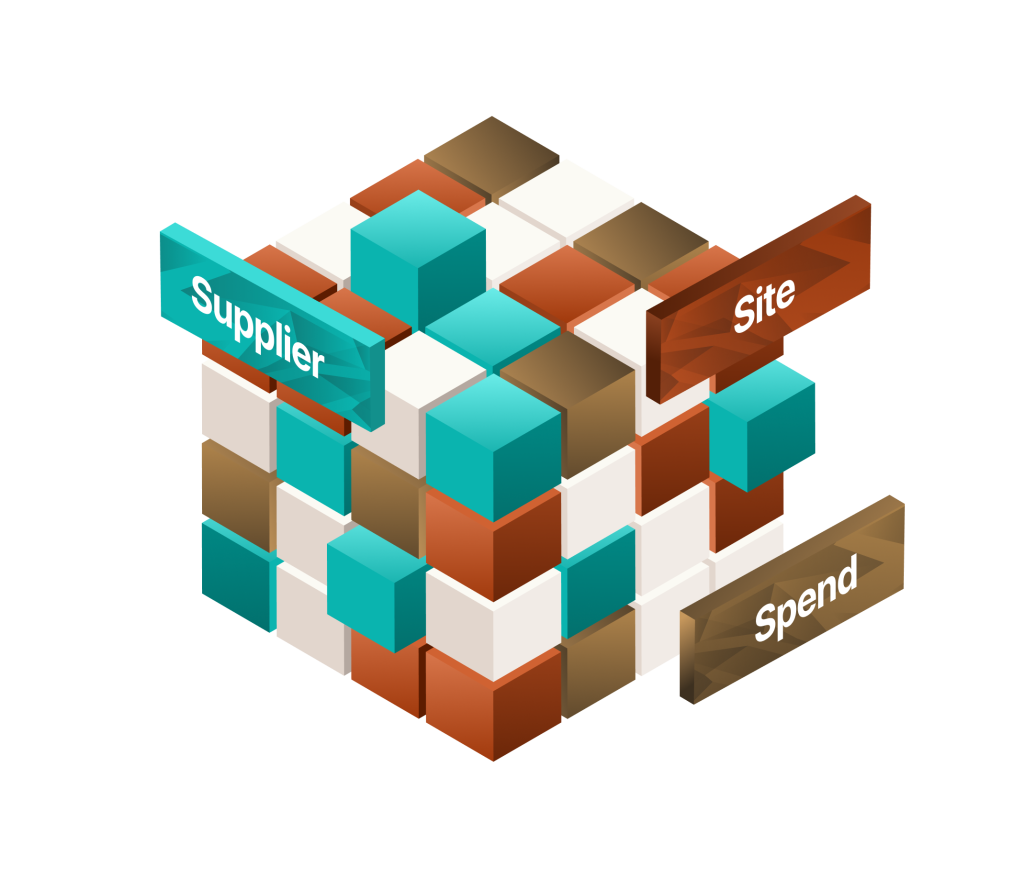

Spend Cube Development

A Spend Cube project was the focus for a $2 billion specialty chemicals company to initiate category management strategy development. By consolidating data from eight ERP systems, the project generated a unified dataset for direct and indirect materials, enabling the development of category plans and sourcing strategies to identify savings opportunities and optimize procurement.

Fleet Vehicles Strategic Sourcing

A $6 billion independent oil and gas company pursued optimization of their fleet vehicles through strategic sourcing and boots on the ground implementation. By implementing a seven-step process, the company revamped vehicle acquisition, upfitting, and fleet services, incorporating telematics and streamlining maintenance and fuel card programs. The initiative, involving a supplier deployed across 26 field offices in four states, resulted in $3.5 million in savings over five years.

Supply Chain Assessment

A U.S. government defense agency had a mission to assess their 5,000+ supply chain staff to improve roles and responsibilities and improve response to mission demands. Through interviews with 800+ employees, the project evaluated job roles and responsibilities, recommending new roles and modifications to improve alignment. The assessment also reviewed procedures and processes, providing recommendations aimed at boosting operational efficiency and effectiveness.

Printed Sleeves Demand Management

A demand planning project by a $7 billion food company aimed at reducing waste and optimizing production processes. The project analyzed operations, meal recipes, equipment, ink usage, and kraft paper sleeves for packaging. Through strategic improvements, such as defining deadlines for changes to nutritional information, negotiating better ink cartridge terms, and forecasting kraft sleeve quantities, the company achieved an 8% reduction in waste and improved its print process.

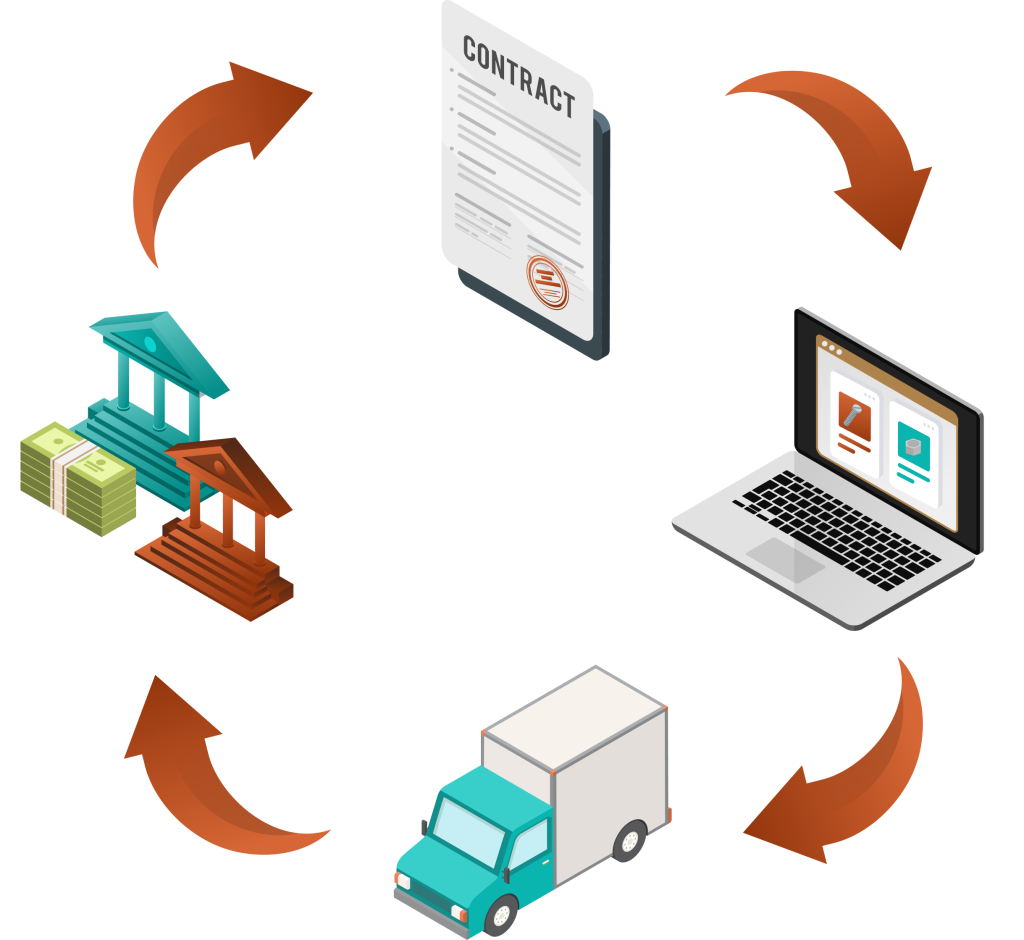

P2P and Contracts Implementation

A Fortune 20 oil and gas company undertook a global rollout to implement Procure-to-Pay (P2P) and Contract Lifecycle Management (CLM) systems. The initiative involved gathering business unit requirements, standardizing master data, and establishing a category hierarchy. After rigorous testing, the solution was rolled out to over 2,000 staff, with training and job aids provided, streamlining procurement processes and enhancing compliance.

MRO Strategy

Maintenance, Repair, and Operations (MRO) procurement is essential to operational efficiency yet often overlooked. A strategic sourcing initiative to aggregate spend and use as leverage for clients in the industrial, food, and consumer goods sectors was initiated. By consolidating spend and leveraging collective buying power, top MRO items were competitively bid, delivering savings of $280,000 to $2.3 million per client. Implementation included negotiated punch-out catalogs, site visits, and streamlined ordering processes.

Reverse Auction Comprehensive Guide

In a competitive retail landscape, a Fortune 50 retailer used reverse auctions to drive cost efficiency across resale and indirect categories. By evaluating opportunities through seven comparability indicators, they prioritized auction suitability and created a standardized sourcing guide.

ART Custom Tool

A $9 billion electric utilities company wanted to unify its’ fragmented procurement processes, artifacts, and reference documents to be easily accessible online and offline. By utilizing Microsoft OneNote, the company created the "All-In-One Reference Tool," consolidating critical resources such as documents, spreadsheets, and market intelligence. This solution improved operational efficiency, collaboration, and staff development.